The key difference is the addition of molybdenum an alloy which drastically enhances corrosion resistance especially for more saline or chloride exposed environments. Stainless steel 304 vs.

The addition of molybdenum provides pitting resistance in phosphoric acid acetic acid and dilute chloride solutions and provides corrosion resistance in sulfurous acid.

Stainless 316 vs 304. Stainless 316 contains more nickel than stainless 304 while 304 contains more chromium than 316. Stainless 304 usually consists of 18 chromium and 8 nickel. Stainless 316 is made up of 16 chromium 10 nickel and 2 molybdenum.

The two steel grades are comparable in appearance chemical makeup and characteristics. After analyzing chemical composition makeup corrosion resistance cost and suitable applications the key difference between 304 and 316 stainless steel is that 316 grade has better corrosion resistance thanks to addition of molybdenum than 304 especially for chloride applications and last longer service life. 304 grade is cost effective choice and performs well for general service selecting which type depend on your application and environment.

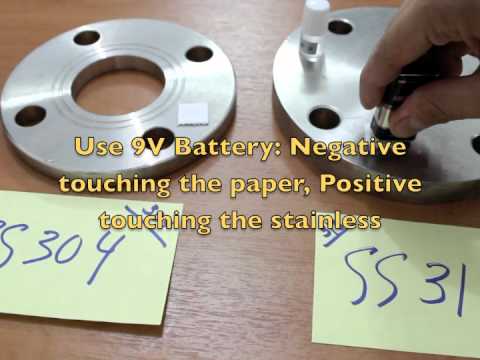

The two most common stainless steel grades are 304 and 316. The key difference is the addition of molybdenum an alloy which drastically enhances corrosion resistance especially for more saline or chloride exposed environments. 316 stainless steel contains molybdenum.

304 stainless steel does not. What s the difference between 304 and 316 stainless steel. The simple answer is 304 contains 18 chromium and 8 nickel while 316 contains 16 chromium 10 nickel and 2 molybdenum.

Stainless steel 304 vs. 316 which is better. Well it depends on the application and needs.

The mechanical properties of both steel sheets are almost the same and both have similar makeup material. Still type 316 has more nickel than type 304 that helps 316 types resist more against chlorinated solutions such as seawater and de icing salts. 304 vs 316 stainless steel.

The main difference between 304 vs 316 stainless steel is the composition and corrosion resistance ss304 doesn t contain molybdenum while ss316 contains 2 3 molybdenum. The addition of molybdenum provides pitting resistance in phosphoric acid acetic acid and dilute chloride solutions and provides corrosion resistance in sulfurous acid. Type 304 with it s chromium nickel content and low carbon is the most versatile and widely used of the austenitic stainless steels.

Type 304 alloys are all modications of the 18 chromium 8 nickel austenitic alloy. Type 316 is an austenitic chromium nickel stainless and heat resisting steel with superior corrosion resistance as compared to other chromium nickel steels when exposed to. When it comes to 316 stainless steel you can expect better corrosion and pitting resistance to chlorides than 304 stainless steel and higher levels of strength at elevated temperatures.

This is due in part to the addition of molybdenum. The 400 series of stainless steel is easier to machine than the 300 series of stainless steel. That includes grade 304 and 316 stainless steel.

However the 304 and 316 grades of stainless steel do differ in their machinability. 316 easier to machine. Type 303 stainless steel is probably the easiest 300 series to machine.

The temperature tolerance of grade 316 stainless steel is close to that of grade 304 being just a little bit lower. As stated in an ak steel data sheet for grade 316 stainless steel the melting range of 316 ss is 2 500 f 2 550 f 1 371 c 1 399 c roughly 50 to 100 degrees fahrenheit lower than the melting point of grade.