The alloys are used widely in equipment and utensils for processing and handling of food beverages and dairy products. Both steels are durable and provide excellent resistance to corrosion and rust.

You know this one already.

304 stainless steel corrosion resistance. 304 stainless steel has excellent resistance to a wide range of atmospheric environments and many corrosive media. It is subject to pitting and crevice corrosion in warm chloride environments and to stress corrosion cracking above about 60 c. It is considered resistant to pitting corrosion in water with up to about 400 mg l chlorides at ambient temperatures reducing to.

Corrosion resistance 304 stainless steel has excellent resistance to a wide range of atmospheric environments and many corrosive media. It is subject to pitting and crevice corrosion in warm chloride environments and to stress corrosion cracking above about 60 c. General corrosion the alloys 304 304l and 304h austenitic stainless steel provide useful resistance to corrosion on a wide range of moderately oxidizing to moderately reducing environments.

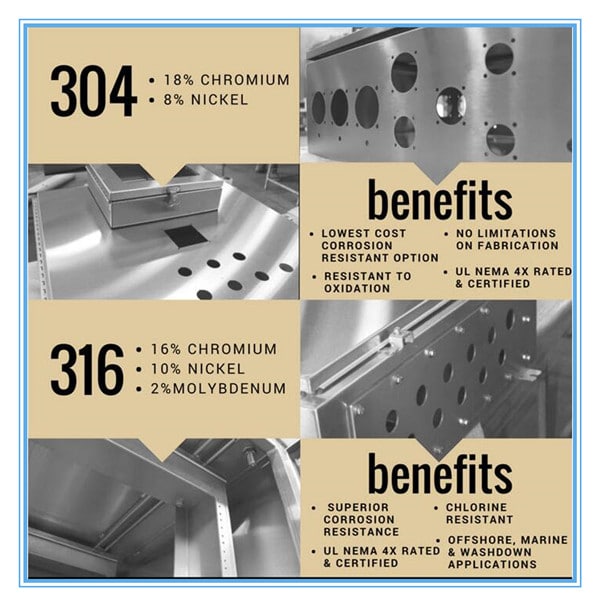

The alloys are used widely in equipment and utensils for processing and handling of food beverages and dairy products. The stainless steel types 304 or 304l are also known as 18 8 stainless because of their chemical composition including approximately 18 chromium and 8 nickel by weight. They are widely used in the food and drink processing industries because they are easy to form and to weld and have a great resistance to corrosion.

Comparision grade 304 304l 316 316l corrosion resistance. As american aisi basic grades the only practical difference between 304 or 316 and 304l or 316l is carbon content. The carbon ranges are 0 08 maximum for 304 and 316 and 0 030 maximum for the 304l and 316l types.

Aisi 304 stainless steel has excellent corrosion resistance in mild atmosphere and fresh water and even the surface will not rust. But it s not resistant to halide such as chloride fluoride etc corrosion because the halide can easily penetrate the passive film and make stainless steel lose the resistance. Carburization heat treatment would only be justified if the corrosion resistance is unaffected.

In this work samples of 304 stainless steels treated by colossal supersaturation case carburizing known as kolsterising carried out by bodycote company was examined for pitting corrosion resistance at room temperature and at 50 c. During the fabrication of stainless steel components or structures it is possible to degrade the corrosion resistance. This occurs when austenitic stainless steels e g.

304 are exposed to temperatures between about 425 c 797 f and 870 c 1598 f. Both steels are durable and provide excellent resistance to corrosion and rust. 304 stainless steel is the most versatile and widely used austenitic stainless steel in the world due to its corrosion resistance.

304 stainless is also cheaper in cost compared to 316 another reason for its popularity and widespread use. What grade of stainless and where did it come from. 316 is more corrosion resistant than 304 but also costs more.

Stainless made in certain countries are of lower quality than that made in other countries and all of it is of lower quality than it was a few decades ago. You know this one already.